CU Pumps

Horizontal centrifugal, single stage back pull-out design in according to ISO 2858 heavy duty PN 16 pumps.

Description

CU

Pumps are horizontal centrifugal, single suction impeller, single

stage, BACK PULL OUT type, design to meet marine and industrial heavy

duties with a high performance centrifugal pump.

CU

Pumps are horizontal centrifugal, single suction impeller, single

stage, BACK PULL OUT type, design to meet marine and industrial heavy

duties with a high performance centrifugal pump.

This pump are design for pressure up to 16Bar and temperature up to

200°C with a life more than 15.000 hours in severe conditions.

Several material selection available to prevent the chemical attack to

the pump materials.

CU pumps are new series of horizontal centrifugal pumps specifically

designed for shipping services to assure cheapest operational costs and

very long working life.

With the use of the most advanced technologies, the new series of

centrifugal CU pumps covers most marine and industrial applications

with medium duty pump.

Design

Horizontal and compact installation with or without bearing

bracket CU or CU/M.

Minimum number of components to facilitate assembly and disassembly

during maintenance

High degree of standardisation of parts for low inventory and effective

spare parts distribution.

Features

Casing:

Computer generated pump volutes for best hydraulic efficiency. Low NPSHr well designed hydraulic patterns reduce losses, improve impeller life and increase suction lift capabilities.

Impeller:

Single suction, designed with low NPSH and high efficiency,

smooth

surfaces and high grade of balancing assure long pump life.Heavy duty

shaft:

Rigid shaft designed for minimum deflection at seal faces less than

0.05 mm. Bearings sized for 15.000 hours average life under tough

operating conditions. Available with or without shaft sleeve.Support

housing with angular contact bearings for longer life:

Shaft supported by radial and thrust bearings placed in an oil bath

bracket or grease lubricated ball bearings, The bearing housing is

normally made of cast iron but are available also special executions

like non magnetic or suitable for high/low temperature for severe

duties and high temperature.

Several combinations of lubrication are available up to Oil mist

lubrication and magnetic bearing protector. Accurate machining and pin

fits assure run-out and concentricity according to ISO specifications.

Seal:

Mechanical seal as standard with seal chamber designed in according to ISO. Several cover are available for severe duties with quelch or heatings/cooling assembly to ensure correct mechanical seal selection for any specific service and long life.

Renevable casing wear rings:

Fixed by screws for ease maintenance. Impeller wear rings are

available as option.

Flexible coupling:

As standard, flexible with spacer as options. Several

combinations are available up to engineered solution.

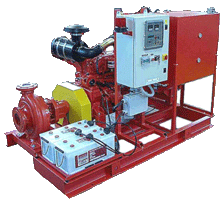

Pump baseplate:

Heavy duty , fabricated carbon steel as standard without drain

as standard. Any other combination are available on request.

Performance Data

Pump capacity up to 1650 m/h

Pump Head up to 150 mt

Working temperature from -30°C to +200°C

Working viscosity up to 350 cst

Speed up to 3600 rpm

Working Pressure up to 16 bar, up to 64 as special

Drive power up to 350kW

Flanges from 25 to 350

Main application

for handling any kind of clean liquid medium with a low or

moderate

viscosity (up to 350cst) , fresh and sea water, condensate, oils,

brines, lyres, petrochemical and chemical products. The fluid to be

pumped must be not containing any abrasive particles.

Services

In shipbuilding: as general service and fire pumps, bilge

ballast and cooling water pumps as well as sea water pumps.

In all industrial branches: for general supply or circulation pump,

cooling and transfer systems.

Spacer coupled

The CU standard model is the spacer coupled version.

The spacer coupled pump offers the advantage of easy maintenance and

does not entail removing the motor. Easy and fast overhaul of pump.

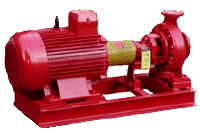

Close coupled

The CU-M close coupled solution is an economical and compact alternative to the spacer coupled version. Simple and robust design. It is the most compact dimension in the market. Dismantling of close coupled pump entails removing the motor to permit access to the pump rotor.