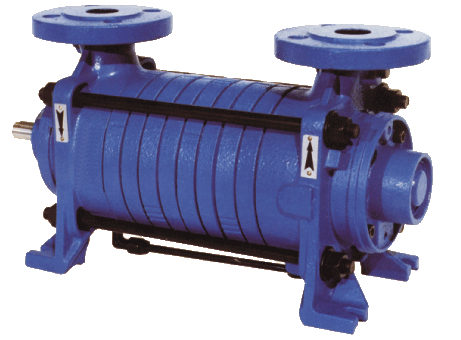

CMA Pump

Selfpriming multistage side channel centrifugal pumps

Description

CMA

Pumps are multistage selfpriming centrifugal side channel type,

available in horizontal (CMA) and vertical (CMAV) installation. The

special open star type impeller, enclosed between the suction and

discharge port plates, allow to handling mixtures of gas and clean

liquids with high suction lift capabilities. The stages are mounted in

series to give proportional higher discharge pressures with constant

capacities.

CMA

Pumps are multistage selfpriming centrifugal side channel type,

available in horizontal (CMA) and vertical (CMAV) installation. The

special open star type impeller, enclosed between the suction and

discharge port plates, allow to handling mixtures of gas and clean

liquids with high suction lift capabilities. The stages are mounted in

series to give proportional higher discharge pressures with constant

capacities.

Low operating speed, low vibration and low noise level allow for longer

life and maximum reliability with heavy duty design allow for to handle

clean liquids, corrosives, hot or cold in all industrial areas. Several

materials are available to meet any client specific requirements.

Design

Horizontal and Vertical and installation with rotor between

bearings supported, modular construction

with minimum number of components to facilitate assembly and

disassembly during maintenance

Features

Casing:

Heavy duty suction and delivery pump casing PN40, radially

split type, sealed by gaskets. The suction and discharge casings are

directed vertically upwards. The suction casing is usually located on

the drive side.

Impeller:

Open, star-shaped impellers, with balancing holes for axial

thrust compensation. Can be moved axially

on the shaft.

Heavy duty shaft:

The particularly rigid stainless steel shaft ensures

trouble-free operation in all services phases.

Support housing with angular contact bearings for longer life:

The shaft turns on both sides in greased, single-channel grooved ball

bearings. These are packed with grease at the factory for 10.000

operating hours.

Seal:

mechanical seal as standard with seal chamber designed in according to ISO. Several solution are available for severe duties with double mechanical seal with quelch or heatings/cooling assembly to ensure correct mechanical seal selection for any specific service and long life.

Spacer coupling:

as standard, flexible type.

Driver frame:

Welded carbon steel, profiled type, torsionally rigid as standard. On vertical pumps the frame is in cast iron with adaptor for standard IEC electric motor

Performance Data

Pump

capacity from 0.3 to 70 m/h

Pump

capacity from 0.3 to 70 m/h

Pump Head up to 350 mt

Working temperature from -20°C to +150°C

Working viscosity up to 250 cst

Speed up to 1800 rpm

Gas contents up to 50%

Working Pressure up to 40 bar

Drive power up to 37kW

Flanges from 32 to 100

Main application

Clear or cloudy liquids of all types can be pumped, provided

that they contain no abrasives.

The pumps are also used for boosting pressure or for any application,

where a self priming pump is necessary or a pump should work trouble

free close to the vaporisation point of the liquid.

Services

In shipbuilding: as general service and fire pumps, process

water pumps, Boiler feed, pressure systems, self-priming systems.

In all industrial branches: for general supply, domestic, cooling and

transfer systems, boiler feed, refrigeration.