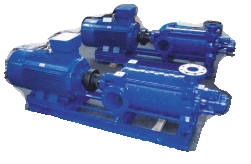

CM Pump

High pressure pumps, multistage centrifugal pumps for high pressure services.

Description

Multistage centrifugal pumps in ring-section design, radially

split

casing heavy duty type, with closed radial impellers and special 1st

stage impeller at for lower NPSH values, primarily designed for power

applications, boiler feed and condensate services in power stations,

industrial plants, desalination and combined-cycle power plants.

Casing parts sealed by O-rings and assembled by robust tie bolts

positioned externally at suction branch. Radial suction and flow inlet

which can be rotated every 90°.

This pump are design for pressure up to 100Bar and temperature up to

180°C with a life more than 15.000 hours in severe conditions.

CM

pumps shall available in horizontal and vertical, with modular design.

CM pumps are suitable for pumping clean or slightly polluted, hot or

cold, chemically neutral or aggressive liquids. Several material

selection available to prevent the chemical attack to the pump

materials.

Design

CM series pumps are of a modular design allowing to find the most efficient solution. Investment cost as well as life cycle cost are taken into consideration when designing the best possible pump. An optimized hydraulic design guarantees best efficiency

Features

Suction and delivery Casing:

computer generated pump volutes for best hydraulic efficiency. Large

branch optimizes inlet flow is

enabled by external positioning of the tie bolts. Reduced noise levels

through low branch velocities. Higher forces and moments allowed.

Impeller:

single suction multistage type with high efficiency. Special 1st stage for low NPSHr, smooth surfaces and high grade of balancing assure long pump life. Every impeller is dinamically balance to assure low vibration.

Heavy duty shaft:

Speed up to 3600 rpm, critical speed higher than operating speed. Heavy duty design assure limit deflection at seal faces less than 0.05mm, under severe applications. All areas subjected to wear are protected by shaft sleeve.

Axial thust dinamically balanced

By balance drum. Eliminates axial thrust problems and allows pump operation with nearly constant thrust over the whole operating time. The drum diameters are chosen to minimize the thrust at normal operating point. The balance drum device carries the major proportion of the hydraulic thrust. The residual and additional thrust loads occurring above/below at the normal operating point are carried by the thrust bearing, typically a taper roller bearing.The balance drum design is suitable for pumps that operate at the end of the curve, up to 130 % of the best efficiency point. The device nearly wear free and therefore suitable for frequent stop start applications.

Casing wear rings

Maintain high efficiency during pump life. Low maintenance cost, high availability and short down times. Impeller wear rings are optional.

Seal:

Packing seal as standard with seal chamber designed in

according to

ISO. Single or double mechanical seal may be installed. Cooled or

uncooled design according to specifications available.

Bearing housing with angular contact bearings for longer life:

accurate machining and pin fits assure run-out and concentricity according to ISO specifications. Standard grease lubrication, but available oil lubrication for severe duties and high temperature.

Coupling:

flexible as standard, without spacer. Available in several solution to meet any client requirements.

Driver frame:

Heavy duty , fabricated carbon steel as standard without drain as standard. Any other combination are available on request.

Performance Data

Pump

capacity up to 800 m/h

Pump

capacity up to 800 m/h

Pump Head up to 1000 mt

Working temperature from -20°C to +180°C

Working viscosity up to 150 cst

Speed up to 3600 rpm

Working Pressure up to 150 bar

Drive power up to 500kW

Flanges from 32 to 200

Main application

Services

These pumps are ideal design for

Boiler feed duties up to 180° C

Condensate service in power stations and industrial plants

Desalination

Reverse Osmosis

Auxiliary services within combined-cycle and industrial power plants

In shipbuilding:

as high pressure services and fire pumps.

In all industrial branches: for high pressure services and

transfer systems.