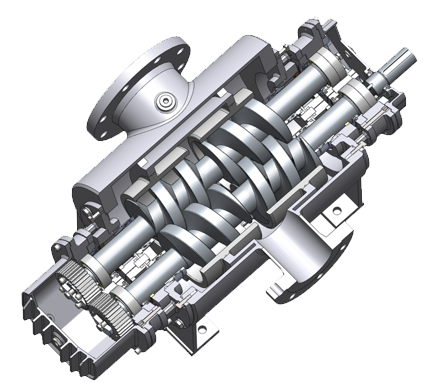

Twin screws Rotary Pumps

A complete range of timed twin screws rotary pumps

Description

The new pumps series production model 2O represents the

evolution of one hundred years of experience in design and construction

of twin screws rotary pumps with internal or external timing device.

The new series has been completely designed and engineered to supply

extremely reliable pumps, even if the working conditions are critical.

Thank to computer aid the hydraulic profile, the components and the

dimensions are fully optimized. That means a compact and solid

construction with an easy to repair feature

The pumps series production model 2O are extremely versatile and can

easy meet customer's requirements.

The wide range of models, materials of construction and

assemblies, for any specific applications, offer a reliable solutions

in accordance with API 676 standard too.

Features

The pumps series production model 20 are provided with a wear resistant inner casing for long life and trouble free operations.The inner casing, cast type, can be supplied in a wide range

of materials to match fluid characteristics.

The

outer pump casing is of compact design type and provided with ample

flow passages to minimize the frictions and increase the

efficiency.

The casing is designed for a working pressure up to 20 bar at

the

maximum temperature of 200°C.

Special features with cooling or heating chamber are also available on

request.

The

nozzles are flange type in accordance with ISO or ANSI standard.

The

nozzles positions are IN-LINE as standard, SIDE-TOP are on request

The

nozzles positions are IN-LINE as standard, SIDE-TOP are on request

All

gaskets are confined O-ring type, supplied in different synthetic

plastic materials. Spiral wound gaskets can be also supplied for high

temperature.

Screw rotors are single bar piece, forged type. On the screw rotor, non

driving end, are located the timing gear.

The

timing position of the screws do not required any adjustment since the

timing gears are positioned by keys, so that the screws never

touch

with one to another. Gears have hardened and rectified teeth profiles

to allow high precision coupling and silent running.

Oversized

roller bearings series NU on the timing gears side and ball bearing

angular contact type on the coupling side are fitted. The bearings can

be easily removed to allow mechanical seal replacement.

The

lubrication of the bearing is grease type on the coupling side and oil

type at the timing gears side. Oil lubrication for both side is also

available, including external circulation if required.

A wide range of solutions about bearings lubrication and

protection are available including V-ring up to bearing protector IP66.

All mechanical seal are supplied in accordance with API682 standard.

Cartridge type mechanical seal are available on request.

All pumps can be supplied with relief valve API520 standard.

Performance Data

Pump capacity up to 1300 m/h

Pumpworking pressure up to 100 Bar

Working temperature from -50°C to +350°C

Working viscosity up to 5000 cst

Speed up to 3600 rpm